New design The possibilities to improve various production lines and speed up processes were evaluated while creating the new model design.

Unlimited functionality. The equipment design can be adapted to industrial manufacturers in various industries, and it is convenient for implementing multiple technical solutions.

Stylistic integrity. The primary product model is the basis of all designed robots of this type.

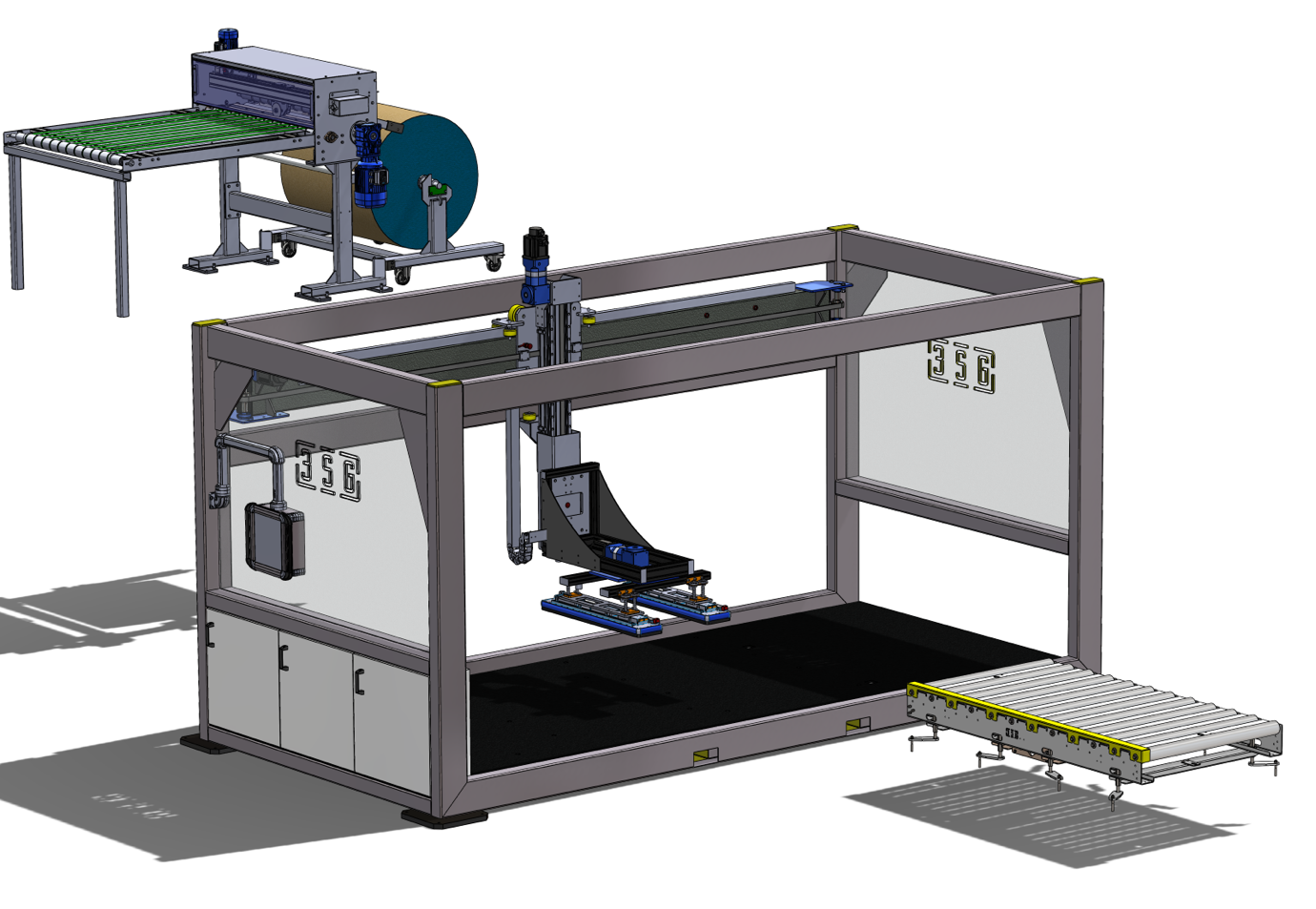

Segmental design. Different segments can be installed on the primary model for various purposes like a belt, roller, segmental conveyors, feeding units, machine tools, etc.

High-security requirements. All moving units that pose a risk to the operator’s health and/or life are separated from all sides by a safety wall.

Comfort and ergonomics. Functional solutions are easy to use when working: the work of the robot and other integrated units is perfectly visible through the plexiglass wall, as well as the equipment components are easy to replace and maintain.

The integrated ergonomic control panel easily controls the robot.

Increased efficiency. When designing the product’s shape, solutions were implemented to optimally reduce the working time of supply managers and mechanics who assemble the product.

Gantry robot

100000,00 €

In the gantry robot system, the line loader, unloader and service station are connected.

A gantry robot is a mechanism designed for the automation and optimization of production lines. With its help, the work of the production line becomes more productive, faster and safer. This type of robot is making a big impact in the manufacturing industry as it enables dangerous and repetitive tasks to be performed with high productivity and error-free. Therefore, more and more factories in the world use these robots.

It can be applied in a manufacturing line of any industry.